|

|

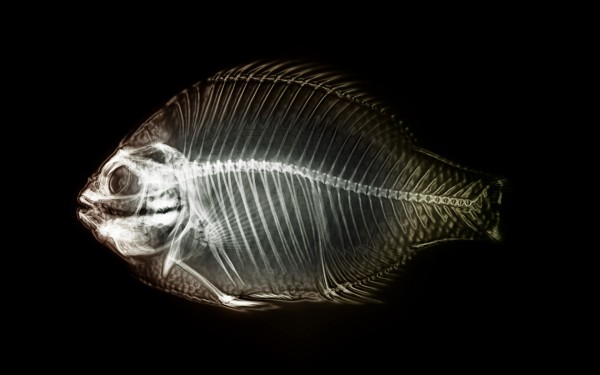

| Hey all, I thought I’d share a new molding process that I’m using. All the previous baits I made were injection molded. It’s a great process but the tools are expensive and you need to buy large quantities of baits at once. I wanted to come up with something that had the same quality and toughness of a molded bait, but I wanted to be able to do it without the big invest and be able to do it at home. If I wanted to be able to mold at home I knew the material would need to be a thermoset material. The mold I designed can run both hand mixed two part casting resins with microspheres, or a hand mixed two part foaming polyurethane. The mold uses an old school “pot and plunger” style of molding. I make a wireform to fit in the mold, clamp the two halves together, mix the material and pour it into the pot, put the plunger in and clamp it, wait about 15-20 minutes for the material to cure, and then open the mold and pop the lure out. As they say, the devil is in the details, but that’s the process in a nutshell.

Is anybody else doing something similar?

Attachments

----------------

MollyDiverCavCor.jpg (98KB - 688 downloads) MollyDiverCavCor.jpg (98KB - 688 downloads)

TopwaterCavCor.jpg (83KB - 449 downloads) TopwaterCavCor.jpg (83KB - 449 downloads)

Molding2.jpg (90KB - 372 downloads) Molding2.jpg (90KB - 372 downloads)

Molding.jpg (74KB - 344 downloads) Molding.jpg (74KB - 344 downloads)

Blanks.jpg (83KB - 478 downloads) Blanks.jpg (83KB - 478 downloads)

|

|

| |

|

Posts: 496

| That is pretty sweet ! Thanks for sharing .

Dinver |

|

| |

|

Posts: 278

Location: Finland | just wondering here are there any advantages in injection molding versus making a mold out from mold silicone and using casting resin? |

|

| |

|

Posts: 1207

Location: Pigeon Forge TN. | Great looking idea.

My question is how you get such big pictures on here as every time I try it won't load cause must be less than 100 whatever bytes.  |

|

| |

|

| SolarFall - 11/5/2012 9:52 AM just wondering here are there any advantages in injection molding versus making a mold out from mold silicone and using casting resin? An advantage of injection molding is the high production capacity. This isn’t thermoplastic injection molding, it is thermoset reaction molding. It’s the same process/materials you are using, but uses an aluminum mold. An advantage to an aluminum mold is that it will last longer, I can insert things into the mold, it can be heated, but mostly it can withstand the pressure form either the foaming polyurethane or the pressure of the plunger when using resin.

|

|

| |

|

| Stan Durst 1 - 11/5/2012 10:05 AM Great looking idea. My question is how you get such big pictures on here as every time I try it won't load cause must be less than 100 whatever bytes. :-) I just downloaded this morning that software in the thread here called resizing photos, I guess it works good. |

|

| |

|

Posts: 1224

Location: Okoboji | how much does an aluminum mold cost? |

|

| |

|

| kodiak - 11/5/2012 11:12 AM how much does an aluminum mold cost? I don’t know, one of my day job contractors likes to fish too. Some people will do work for baits or just think it’s cool to machine something like that. I do give him lots of real work too though ;-)

I’d say that’s less than a couple of hundred buck’s worth of Aluminum, he used scrap.

|

|

| |

|

Posts: 532

| kodiak - 11/5/2012 12:12 PM

how much does an aluminum mold cost?

Alot of things come in to play with a cost of an aluminum mold. Size, number of cavities, if adapting to a press, completity of the part, if you have a 3d part file...

I have made aluminum molds for several business's that make baits, some are on this site. But every mold is different but a range would be $500 on the low to $5000+ for multicavity full production molds.

For the standard basement builder it is sometimes hard to justify, but they are nice |

|

| |

|

Posts: 2

| Hi,

What are you using as a mold release?

This is really exciting. reading this totally blew my mind.

I was thinking of making cast aluminum molds for casting two part urethane resin.

The resin can be colored, so there's no reason that individual pieces in different colors couldn't be molded separately and then combined in one body mold with the final resin part holding it all together. Plus there are clear casting rubbers that could be over-molded to give the lure the proper "mouth feel" for a hungry fish to chomp on.

Usually resin is cast into silicone molds, but the resin eats up the molds quickly, so the fact that you're using rigid metal molds is very interesting.

stez

|

|

| |

|

| Stez - 4/13/2013 1:25 PM Hi, What are you using as a mold release? This is really exciting. reading this totally blew my mind. I was thinking of making cast aluminum molds for casting two part urethane resin. The resin can be colored, so there's no reason that individual pieces in different colors couldn't be molded separately and then combined in one body mold with the final resin part holding it all together. Plus there are clear casting rubbers that could be over-molded to give the lure the proper "mouth feel" for a hungry fish to chomp on. Usually resin is cast into silicone molds, but the resin eats up the molds quickly, so the fact that you're using rigid metal molds is very interesting. stez

I use a high temperature mold release wax and hand polish it on every 10 or so lures. There are many other spray on mold release systems out there. Believe it or not Pam cooking spray works pretty well. Your mold will need to have sufficient draft in the cavity and core and the aluminum needs a good polish as well. You’ll notice a pin in mold inside the eye area of the lure, after molding I use that to pop the lure out. Urethane is sticky stuff!

Edited by MRichardson 4/15/2013 9:15 AM

|

|

| |

Low Budget Molding

Low Budget Molding Low Budget Molding

Low Budget Molding