|

|

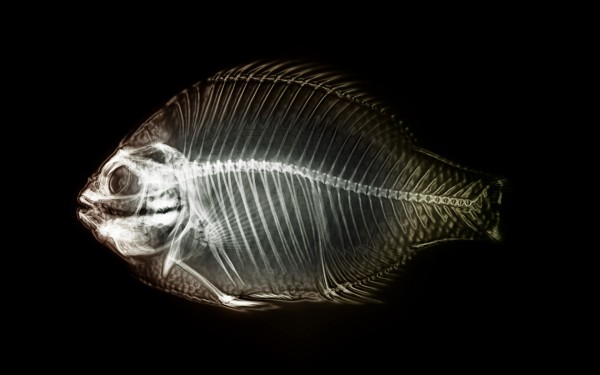

| So I decided to make a big fiberglass tackle box for my bigger lures 28X16X14. I have the sides glued together but I don't really know how to make the individual spaces. Do I gotta cut them all and glue them together? Like I would have 5 long pieces going the 28" across and I was thinking about doing 2.5" square spaces. Is there an easier way to do it so I don't have to glue so many 2.5" X14 pieces to make up the individual spaces?

(PicsArt_1349310882525.jpg)

Attachments

----------------

PicsArt_1349310882525.jpg (135KB - 298 downloads) PicsArt_1349310882525.jpg (135KB - 298 downloads)

|

|

| |

|

Posts: 63

| look at making each one a solid piece across with notches in it much like the plano boxes.. |

|

| |

|

| So the long pieces are solid and the ones that go short ways notch them out and slip em over the long solid pieces? |

|

| |

|

Posts: 865

| Neatly cut plastic Gutters to the height, and then just notch the top in the center of each side. They can be easily removed if wanted |

|

| |

|

Posts: 432

Location: Eagan, MN | Cut a slot halfway through all of the dividers. All of the dividers going lengthwise should have the slots pointed one way (up or down) and all of the dividers going cross-wise should have the slots pointed the opposite direction. The dividers should meet at 90 degree angles and mesh together. Kind of hard to explain. |

|

| |

|

Posts: 8863

| I think I can explain it. Take the dividers out of that Plano 7915 box to the left and see how they are cut and how they fit together. That's what you want to do with yours. |

|

| |

|

| Makes perfect sense. Thank you. |

|

| |

|

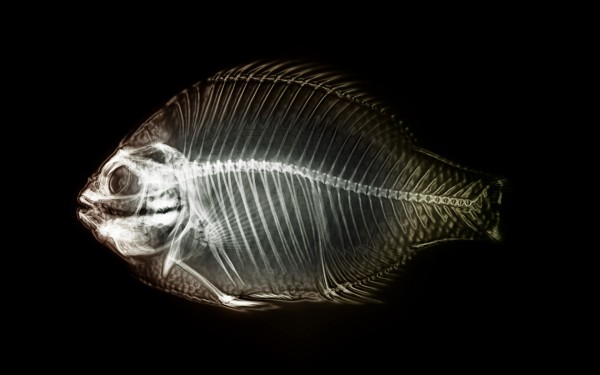

| Like this right?

(PicsArt_1349440088822.jpg)

Attachments

----------------

PicsArt_1349440088822.jpg (135KB - 366 downloads) PicsArt_1349440088822.jpg (135KB - 366 downloads)

|

|

| |

|

Posts: 432

Location: Eagan, MN | Exactly. Nice work. |

|

| |

|

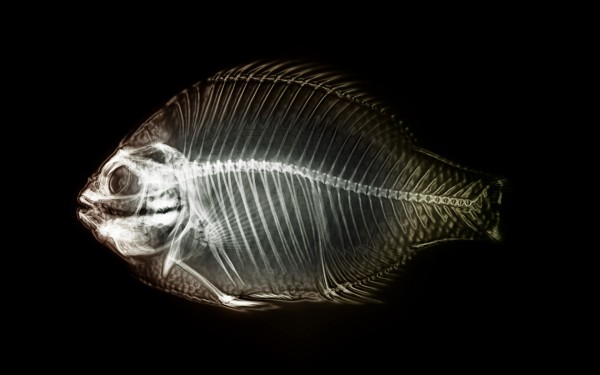

| Basically done.

(PicsArt_1349747178033.jpg)

Attachments

----------------

PicsArt_1349747178033.jpg (135KB - 1152 downloads) PicsArt_1349747178033.jpg (135KB - 1152 downloads)

|

|

| |

|

Posts: 1638

Location: Minnesota | looking good |

|

| |

|

Posts: 797

Location: North Central IL USA | Cool! |

|

| |

|

Location: Des Moines IA | Fiberglass? You mean Acrylic? As far as I knew you can't see through fiberglass? |

|

| |

|

Posts: 1098

| Looks nice heres how i made mine

Attachments

----------------

hpim7737.jpg (134KB - 1353 downloads) hpim7737.jpg (134KB - 1353 downloads)

|

|

| |

|

Posts: 1638

Location: Minnesota | are you going to put lids on them |

|

| |

|

| I'm gonna drill holes in the bottom of mine and leave it open probably |

|

| |

|

Posts: 1224

Location: Okoboji | you used the solvent to weld the seams right? |

|

| |

|

| Yeah I used the epoxy e6000 for the seams. Clamped it and let it cute for 2 days for each seam.

I know I should have done a how to on it but I forgot. |

|

| |

|

Posts: 1157

| I've built a couple of boxes like this myself. One thing to consider is where you will put the box. The first two that I made were nice but they took up a lot of room in the boat (Lakewood or Plano's would do the same). So, the beauty of any DIY project is you can do it however you want and sometimes completely re-design things after you are already under way.

Prior to building my last one this spring, I rebuilt the front deck in my boat, then built a new box to fit under the deck. I have two carpeted lids running down the center of the box (resting on aluminum rails) so I can lift one lid to access the front part of the box and one for the back section. Really turned out nice and has been very functional in the boat this year. Two big reasons I like having my box under the deck is 1) out of sight, out of mind, I don't worry about people stealing lures at every gas station or restaurant stop because they can not see them. 2) Safety of other people in the boat, especially my nephews on camping trips and such, I don't have to worry about them getting into lures and hooking themselves. At the end of a trip, the box slides right out and can be taken inside. I'll get a couple pictures of my set up.

On a side note, I am not familiar with e-6000 epoxy but I would use either the Weld-on 3 product that is made for bonding acrylic to itself or use hardware like the other guy did here. It would really suck if you were carrying your new box to the boat and it broke apart and dumped your baits all over. |

|

| |

|

Posts: 128

| MartinTD - 10/9/2012 9:29 AM

I've built a couple of boxes like this myself. One thing to consider is where you will put the box. The first two that I made were nice but they took up a lot of room in the boat (Lakewood or Plano's would do the same). So, the beauty of any DIY project is you can do it however you want and sometimes completely re-design things after you are already under way.

Prior to building my last one this spring, I rebuilt the front deck in my boat, then built a new box to fit under the deck. I have two carpeted lids running down the center of the box (resting on aluminum rails) so I can lift one lid to access the front part of the box and one for the back section. Really turned out nice and has been very functional in the boat this year. Two big reasons I like having my box under the deck is 1) out of sight, out of mind, I don't worry about people stealing lures at every gas station or restaurant stop because they can not see them. 2) Safety of other people in the boat, especially my nephews on camping trips and such, I don't have to worry about them getting into lures and hooking themselves. At the end of a trip, the box slides right out and can be taken inside. I'll get a couple pictures of my set up.

On a side note, I am not familiar with e-6000 epoxy but I would use either the Weld-on 3 product that is made for bonding acrylic to itself or use hardware like the other guy did here. It would really suck if you were carrying your new box to the boat and it broke apart and dumped your baits all over.

Yes post up some pictures! |

|

| |

|

Posts: 128

| One thing I've noticed......Once you buy materials, the cost is very high. Makes buying one of the pre fabbed and available boxes like this much more attractive |

|

| |

|

| Well this one is going to stay on my boat no moving. It fits right next to the console and the rod locker on the other side. And it buts up against the front casting deck. I have a Plano box that's sorta in one of the pictures ill use if I'm taking baits somewhere.

But yours sounds like an awesome idea. My casting deck is only about 4 1/2 wide and 4 ft tall so its short and narrow. I don't have much room to do anything up there. |

|

| |

|

Posts: 1224

Location: Okoboji | no i used the stuff that "welds" the plastic together you just clamp it and use the metal syringe applicator and it welds it too a hard quickly set up clear seam. |

|

| |

|

| This is where its installed.

(PicsArt_1349816814240.jpg)

Attachments

----------------

PicsArt_1349816814240.jpg (133KB - 273 downloads) PicsArt_1349816814240.jpg (133KB - 273 downloads)

|

|

| |

|

| What did you use to cut the stuff? |

|

| |

|

Posts: 293

| You can just rip acrylic down on a table saw...just go slower so you don't chip it up bad. |

|

| |

|

Posts: 615

Location: Madison, WI | MartinTD

Would love to see some pics of your tackle box / casting deck.

Cool ideas being debated here love the boxes guys....well done!!!

MS |

|

| |

|

Posts: 1157

| MuskyNate27 - 10/11/2012 12:37 PM

You can just rip acrylic down on a table saw...just go slower so you don't chip it up bad.

I used a jigsaw with blades specifically for Plexiglass. Works great too. |

|

| |

|

Posts: 1157

| Here are pictures of what I was describing. You can see there used to be a step going to the front deck and wasted space in between the consoles. That is where I mounted the aluminum rails and built the box to fit inside the hole. Then carpeted a couple pieces of thick treated plywood for 'new' expanded front deck which doubles as tackle storage. When I get home for the day I lift the two center deck sections and lift the box right out. Plus I really like having all of the lures out of sight. It's worked out nice for me this season. The tray I made that covers what used to be the front step works great for release tools and the tray in back for keys, phone, and other junk. Functional.

Edited by MartinTD 10/12/2012 4:50 PM

Attachments

----------------

Boat Deck 001.JPG (81KB - 226 downloads) Boat Deck 001.JPG (81KB - 226 downloads)

Boat Deck 002.JPG (83KB - 265 downloads) Boat Deck 002.JPG (83KB - 265 downloads)

Boat Deck 004.JPG (95KB - 349 downloads) Boat Deck 004.JPG (95KB - 349 downloads)

Boat Deck 005.JPG (78KB - 238 downloads) Boat Deck 005.JPG (78KB - 238 downloads)

Boat Deck 007.JPG (84KB - 297 downloads) Boat Deck 007.JPG (84KB - 297 downloads)

Boat Deck 008.JPG (85KB - 249 downloads) Boat Deck 008.JPG (85KB - 249 downloads)

Boat Deck 009.JPG (91KB - 269 downloads) Boat Deck 009.JPG (91KB - 269 downloads)

|

|

| |

|

Posts: 1157

| Here's a couple of the box. You can see it is tapered to fit the opening between the consoles perfectly. Also, on this one I just did straight cross sections for holding baits. I've found it actually works a little better because you are not limited on the slot size. I try to stagger lures for the most part and it keeps them separate just fine.

Edited by MartinTD 10/12/2012 4:57 PM

Attachments

----------------

Boat Deck 010.JPG (60KB - 297 downloads) Boat Deck 010.JPG (60KB - 297 downloads)

Boat Deck 011.JPG (62KB - 252 downloads) Boat Deck 011.JPG (62KB - 252 downloads)

|

|

| |

|

Location: Eastern Ontario | Nice work |

|

| |

|

Posts: 615

Location: Madison, WI | MTD

That is beautiful work......well done!

MS |

|

| |

|

| kodiak - 10/9/2012 11:09 AM

no i used the stuff that "welds" the plastic together you just clamp it and use the metal syringe applicator and it welds it too a hard quickly set up clear seam.

Kodiak: Do you know the name of the stuff you used?

For everyone else: What did you use to adhere, melt, weld, etc. the acrylic to itself at the corners? |

|

| |

|

Posts: 1224

Location: Okoboji | catchandrelease - 10/13/2012 8:38 PM

kodiak - 10/9/2012 11:09 AM

no i used the stuff that "welds" the plastic together you just clamp it and use the metal syringe applicator and it welds it too a hard quickly set up clear seam.

Kodiak: Do you know the name of the stuff you used?

For everyone else: What did you use to adhere, melt, weld, etc. the acrylic to itself at the corners?

i will get that for you. |

|

| |

|

Posts: 62

| kodiak - 10/16/2012 8:41 AM catchandrelease - 10/13/2012 8:38 PM kodiak - 10/9/2012 11:09 AM no i used the stuff that "welds" the plastic together you just clamp it and use the metal syringe applicator and it welds it too a hard quickly set up clear seam. Kodiak: Do you know the name of the stuff you used? For everyone else: What did you use to adhere, melt, weld, etc. the acrylic to itself at the corners? i will get that for you. the chemical you use to bond or "weld" plastic depends on the type of plasic. i.e. for polycarbonate,acrylic, and styrene its best to use mek. but mek will not work for polypropalene and polyethelyne however other solvents will. it just depends on the chemical makeup of the plastic. btw martintd nice work on that below deck box! thats quite slick. |

|

| |

|

Posts: 293

| I used a product called "Weld on 4". However for some reason it didnt seem to work very well on polycarbonate, but worked extremely well on just regular acrylic. There are some good videos on youtube. Biggest thing I found is to have very clean edges...sanded and polished with a map torch. |

|

| |

|

Posts: 128

| Nice work by all you guys.

I'm beating a dead horse here on the cost, but unless I'm missing something building your own will be pretty expensive, with little savings over the already available pre-made boxes like this.

Where are you guys getting your materials? |

|

| |

|

Posts: 1638

Location: Minnesota | you guys did some nice work..i dont have the time so i bought one built by just encase love this deck box

Attachments

----------------

IMG_0094 (Copy).JPG (29KB - 215 downloads) IMG_0094 (Copy).JPG (29KB - 215 downloads)

IMG_0097 (Copy).JPG (35KB - 226 downloads) IMG_0097 (Copy).JPG (35KB - 226 downloads)

|

|

| |

|

Posts: 1157

| Funny story, UPS delivered a BIG angle iron frame box that was covered in Makrolon to my work. The thing is, NO ONE ordered it. This box sat around for over a year unclaimed, then we wanted to get rid of it so I said I'd take it. I had to remove all of the panels from the frame but then I had a lot of material to work with. Free. Menards or the like carry some material but not sure exactly what and I know it's expensive.

The JustEncase boxes are obviously nice and more professional looking. If I had a nicer, newer boat I may look at getting a couple of them. But c'mon man, I paid $1200 for my boat 5 years ago. You have more than that in JustEncase boxes! Just saying. |

|

| |

|

Posts: 293

| I manage stock at a bus window manufacturing company....needless to say I can get my hands on alot of Poly carb, and plexi. |

|

| |

|

Posts: 1638

Location: Minnesota | your right there not cheap.i would be a rich man if i could give up hunting and fishing bought a new boat this year. 2011 suv was not big enuff to pull it. bought a new truck. bought new fish finders spent more on them then i should have im just keeping this country form going in debt any further just this year .as you can tell im not married LOL |

|

| |

my own fiberglass tackle box

my own fiberglass tackle box my own fiberglass tackle box

my own fiberglass tackle box