|

|

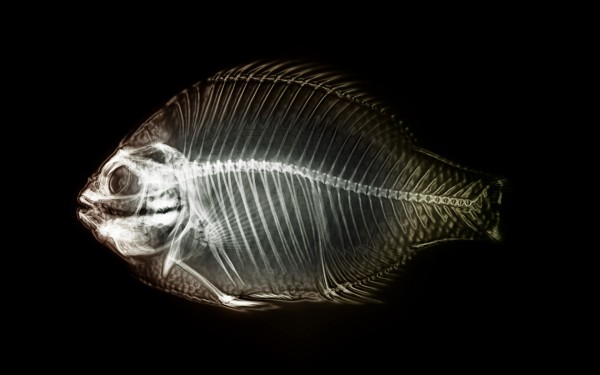

| I’ve always wanted to do a creeper, so I started working on some concepts. After working on it some I noticed the eyes made it kinda look reptilian, I think I’ll try to emphasize that look a little bit more. Don’t think I’ll be able to justify an injection mold so I’ll probably do a through wire resin cast mold. I’d like to be able easily modify it for some prop and flaptail versions. What do you think?

Attachments

----------------

creepconcept a.JPG (37KB - 261 downloads) creepconcept a.JPG (37KB - 261 downloads)

creepconcept b.JPG (31KB - 276 downloads) creepconcept b.JPG (31KB - 276 downloads)

creepconcept c.JPG (36KB - 252 downloads) creepconcept c.JPG (36KB - 252 downloads)

|

|

| |

|

Posts: 1224

Location: Okoboji | MR RICHARDSON what program is that..i must have it. |

|

| |

|

| It’s a CAD system called Solidworks. I can use that file to cut prototypes from wood, then when ready I’ll cut an aluminum mold for casting. |

|

| |

|

Posts: 286

Location: VA | If you build it I will buy it. Great looking bait |

|

| |

|

Posts: 615

Location: Madison, WI | AWESOME!!!!!!!!!!!

Love me some creepers!

MS |

|

| |

|

| Well all right, thanks! That’s interest enough for me. The creeper just got bumped to the top of my list. I was going to do a 11” MDR Chopper or 14” Molly Bait next, but I can’t wait to figure this creeper out. This is what I love most about bait making, feeling that passion to overcome and figure out all the challenges. Has anyone ever done a flaptail creeper? I think that may pose some unique challenges. Cheers! |

|

| |

|

Posts: 1150

| kodiak - 2/23/2012 1:09 PM

MR RICHARDSON what program is that..i must have it.

LOL! We use Solidworks at work in addition to AutoCAD and it ain't cheap. That's why only the guys who really know how to use it get seats. Awesome tool for doing assembly drawings especially.

Not an easy program to self teach though. |

|

| |

|

| I would disagree with the comment of not being able to self teach. It is a pretty intuitive program for most functions. The sheet metal stuff is where it gets a bit sketchy. For someone that doesn’t work in CAD for a living it would be expensive to get into though.

Mike you say you can use it to cut your wood proto. Are you using wood in a machine run off of the solid model to create the proto, or just to get a template to manually shape out of wood?

|

|

| |

|

| By the way Mike I like it, but what the hell do I know I don't throw creepers!  |

|

| |

|

| I use a cnc milling machine that’s used for metalworking. Since I design the baits to be molded, I first figure out my parting line and make sure I have no undercuts and plenty of draft for release. I design a flat around the parting line of around .080 so I can either insert mold some figure 8’s or a thru wire. Since I have this flat, it becomes a 2D profile. I use that profile and the parting line flat to become a web I leave standing in the wood when machining. Since everything is “in the direction of pull” I can use a ball endmill to reach and cut all details. So you design a piece of wood with the bait centered in it that has this web profile, run it through the CAM system to create the cutter paths, clamp a piece of wood in the vice, machine one half, flip it over and find zero again, machine the other half, take it out and punch the bait out of the web, sand the flat off, and “voila” a prototype shape is ready for testing. How’s that for a bunch or run-on sentences? Did that answer your question guest? No I don’t do any hand shaping; the prototypes look exactly like the molded part because they are made from the same file I increased the eye area so I can fit a 10mm glass taxidermy reptile eye. Whew, with the glass eyes, wings, and flaptail, this thing is getting pricy! Lol Expensive Hobby!

Edited by MRichardson 2/24/2012 2:23 PM

Attachments

----------------

creepconcept d.JPG (88KB - 256 downloads) creepconcept d.JPG (88KB - 256 downloads)

|

|

| |

|

Posts: 615

Location: Madison, WI | BADD ASS, I'd be happy to beta test the first one for you

Great job

MS |

|

| |

|

| Nice creeper, I would buy a couple.

|

|

| |

|

Posts: 941

Location: Freedom, WI | Pretty cool Mike. To justify the cost of a mold I believe would be questionable with a creeper. The creeper market is only so big, considering it is unique might be enough. Make it so you can use the same body in other configurations and it would be a go. I have about 3 or 4 dancing in my head right now. |

|

| |

|

Posts: 305

| Your molly and MDR chopper are both underrated, Mike. I would definately try your creeper in a flaptail version with spreaders. Same for 11" MDR chopper. |

|

| |

|

Posts: 284

| put a lip on that thing and a really long rubber tail and I am interested. Looks just like a snake. I can see it swimming in the shallow already. |

|

| |

|

| Hey thanks guys, ya I definitely can see a few different topper version baits to go along with a few different creeper styles. I thought about some lipped options like ghitierman said, with and without rubber. So the concept’s a go and I’ll have other options besides the creeper. So thanks for the input guys! Heck I even received a PM to do an offshoot of the coot concept – lol Esoxlucifer, hey thanks man, I like hearing that, I hate tooting my own horn, but I also think my baits are underrated like you said. I’m a bad business man; I hardy do anything to promote the baits or even focus on sales efforts for that matter. I’m mainly motivated to do R&D, but hey that’s why I do this. Maybe someday a big shot will come along, buy me out, and give the baits the proper attention they deserve – ha ha! Wishful thinking! |

|

| |

|

Posts: 5

| MRichardson I use inventer and have tons of lures already modeled. I can send you over the DXF or IGES files if you want to take a look. Let me know. My email is [email protected]

|

|

| |

|

| Hey that’s cool Paul; I started out in AutoCAD many many years ago. When they came out with mechanical desktop I decided to go with Solidworks instead back with version 97’. I’ve been using it ever since. I just started training and bought a seat of Creo (Pro-E) software just to get some business. It’s weird when customers make you do that. So far it looks like some pretty cool software. I think all systems are starting to interface the same.

I have many lures designed too, share them on here if you’d like, the problem for me is spending the dough on prototypes and tooling. Someday I’ll have a CNC in my basement…

Here’s a crank I’d like to do someday

Attachments

----------------

crankAssem1.JPG (84KB - 306 downloads) crankAssem1.JPG (84KB - 306 downloads)

|

|

| |

|

| Mike you gotta come out with that crank! However not sure I would have the curved lip on the top side though. |

|

| |

|

Posts: 5

| MRichardson that is a nice design. I have never worked with and wood CNC and I'm not sure what the difference if any there is from metal. Do you ever get any ofr your baits CNC cut? Do you use Master Cam for the programming? I am a Mechanical Engineer and have been putting a lot of my knowledge into making lures. I have been searching for a CNC shop to make some lures for me. Any advice? At the moment I am making lures by hand. I will post some pictures here sometime soon.

It is great to see someone else besides me is this crazy about lures  |

|

| |

|

| I will do that crank, probably next year. You’re right, no it won’t have that lip, not that I couldn’t get it to work, but I need to lessen my capitol output when doing these. It will have a standard shape polycarbonate lip. Yes I have used Mastercam and other cam programs as well. I use standard metal working VMC’s – Mazak, Hass,Fadel etc... When you design your bait, design a web about 1/16” into it and apply your cutter paths including that. Surface cut both sides with a ball end mill then use a standard endmill to slowly cut down the web profile and then beak it out and sand. Any shop in your area should be able to quote this for you.

Attachments

----------------

MDR ChopperA Web.JPG (92KB - 242 downloads) MDR ChopperA Web.JPG (92KB - 242 downloads)

|

|

| |

|

| Screw the creeper and do that crank this year!!!

What do you need to do that crank this year?  |

|

| |

|

| LOL, How about you give me a PO for 2,500 pieces @ $11 ea. and I’ll put you in business, you can help develop the color patterns, own the tooling, and take over from there |

|

| |

|

Posts: 1224

Location: Okoboji | i'll do your paint lol |

|

| |

|

Posts: 2089

| The creeper looks awesome, but I want a 14" Molly!!!!! Oh my Gawd would they eat that!! |

|

| |

Creeper concept

Creeper concept Creeper concept

Creeper concept